|

||||||||||||||||||||

|

||||||||||||||||||||

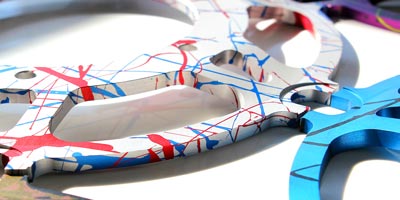

Services Professional expertise and over 100 years experience Reeve Metal Finishing, a leading Midlands-based metal finishing company, are one of the UK's leading anodisers, offering aluminium anodising services along with polished aluminium, brass or stainless steel, with manual vat capacity for anodising. We offer top-quality aluminium polishing services and outstanding results, for one-off orders and bespoke projects. Our full list of metal and aluminium anodising services include:

|

||||||||||||||||||||

Website designed & hosted by vista360 web solutions | email: websolutions@vista360.co.uk Site Map: HOME PAGE | ABOUT US | SERVICES | CONTACT US Whilst every effort has been made to ensure accuracy on this website, vista360 Limited can accept no liability whatsoever for any errors, inaccuracies or omission, or for any matter in any way connected with or arising out of the publication of this information. © copyright 2022 Reeve Metal Finishing Company - Chrome Plating - Anodising Specialists - Zinc Plating - UK and Ireland |

||||||||||||||||||||